Techflow Enterprises Pvt Ltd is expertly one of the most entrusted and largest suppliers of products like Pulse Jet Bag Filter For Kiln, Bag House, Dust Recovery System, Furnace Fume Extraction System, Air Pollution Control Device, Online Cleaning Bag Filter, De-Dusting System, Electrostatic Precipitator, ESP, Bag Filter, Silo Vent Filter, Cassette Type Filter, Flue Gas Emission Control System, Air Pollution Control Equipment, Reverse Air Cleaned Bag Filter For kiln bag Filter For Kiln, Centrifugal Fans & Blowers, Fabric Filter, Pneumatic Conveying System, Welding Fume Extraction System, Pulse Jet Dust Collector, Offline Cleaning Bag Filter, to different industries domestically and worldwide.

We, at Techflow Enterprises Pvt Ltd, have been providing essential mechanisms to numerous industries like Cement, Kiln Exhaust, Mining and Minerals, Air Pollution Control Systems, Particle Board Manufacturing, Boilers Flue Gas, Coal Handling, Foundry & Steel, Solid Drying, Wood-Working & Laminates, Hot Gases and Fumes, Glass, and many more industries.

Discover more| Bag Filter for Kiln Applications |

|---|

Bag Filter for Kiln are fundamentally used to cause steam for Power Plants, Sugar Mills, Chemical Plants, Process Houses, and more. To induce steam, these Boiler Flue gas use Renewable Solid Fuels, Energy, Electricity, LPG, Gas, and Oil. Out of the detailed fuels, solid fuels are the most affordable and the most used source though existing the most polluting. To maintain the emissions of these solid fuels, TECHNOFLOW manufactures and supplies highly efficient emission control systems. These systems are known around the world in many terms such as bag filters for boiler flue gas, pulse jet bag filters, dust collection systems, pulse jet bag filters, ESP for boilers, bug houses, bag filters, etc. There are different types of pollution control devices or bag filters to prevent the emission of different types of solid fuels, such as boiler flue gas bag filters, coal-fired boiler bag filters, bagasse-fired bag filters, bagasse-fired bag filters, food, etc. Bag filters for agricultural waste-fired boiler bags, waste incineration boilers, and wood-fired boilers. TECHFLOW proudly supplies everything as needed. |

Techflow is a certified manufacturer and supplier of bag filters for oven-type air pollution control systems based in Ahmedabad, Gujarat. Exported worldwide, Techflow's customer-focused system, providing the industry's best air pollution control solutions, has become a reliable partner in many industry segments and needs the best bag filters for kilns. Being the best partner to meet. |

The main plants to which the boiler's air pollution control system is typically supplied are cement plants, steel mills, dairy products, power plants, paper mills, chemical plants, sugar plants, pharmaceuticals and processing plants. |

Based on fuel and exhaust gas needs, TECHFLOW is innovating and supplying pollution control systems and pulse jet bag filters for boiler flue gas. Below are two main types of pulse jet bag filters used by TECHFLOW to adjust boiler dirt. |

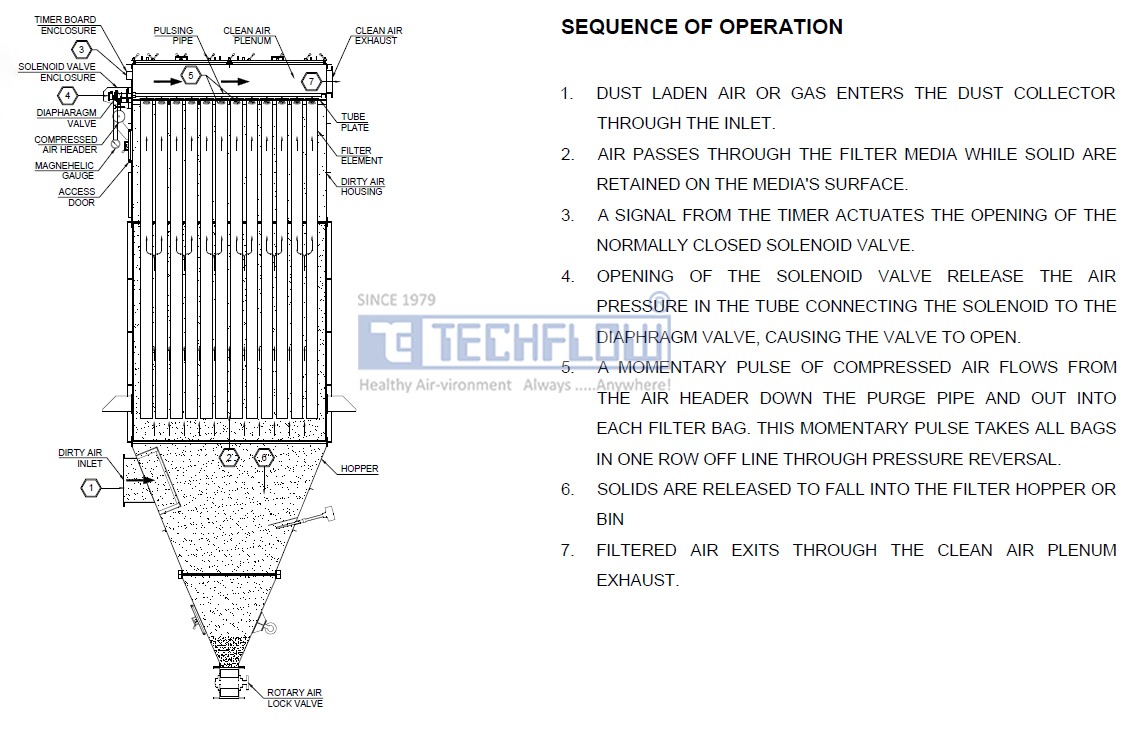

1. Online cleaning pulse jet bag filter for kiln

When heavy particles fall out of the airflow, dusty air enters the funnel. Light particles are trapped in the air and rise into the filter bag. As air passes through the filter bag, dust molecules collect on the outer surface of the filter bag as clean air is expelled from the collector. A jet of compressed air flowed through the venturi at specific intervals through the impulse and blow tubes. It contains a robust secondary airflow that temporarily reverses on the pocket. This creates an internal shock wave that pressurizes and rotates outward as the shock propagates in the length of the bag. This process can remove the backflow dust on the outside of the bag, which will fall into the collection hopper. The flow of air over a series of pockets is reversed by this process, but only for a moment. This allows a constant amount of air to flow throughout the dust collector. The cleaning process can be easily controlled and configured via the solid state timer. The full adjustment of the timer is enabled and managed by the differential dynamometer. To minimize the consumption of compressed air during operation, the pulse pause and duration can be set accurately and absolutely with a timer.

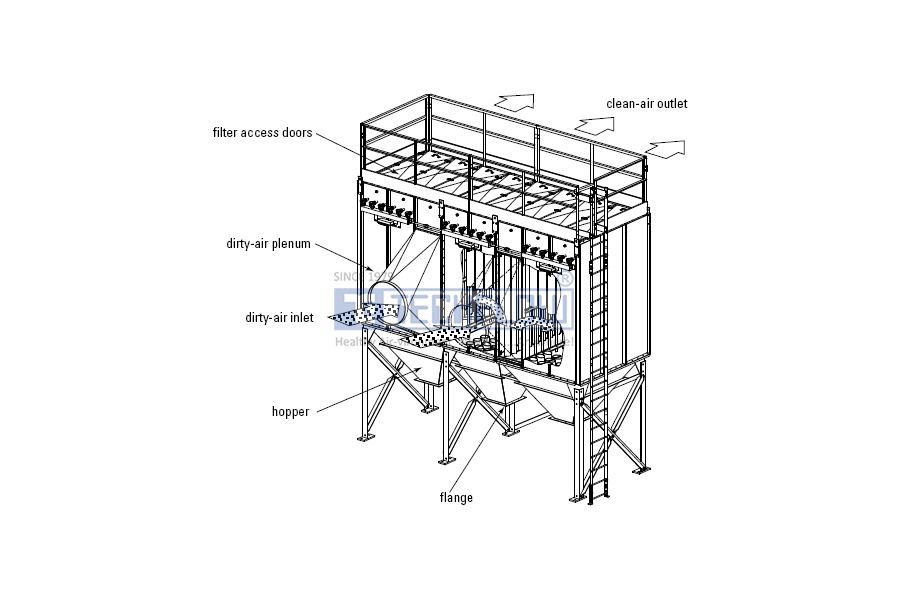

2. Off-line cleaning pulse jet bag filter for Kiln

The pulse jet hose chamber can also be split. In this process, the slug of dirty air into the chamber is controlled by a gate / poppet valve mounted on a clean air plenum. Equipped with a single pulse valve that supplies compressed air to a set of bags in individual compartments, or blows pulsed air directly into the blow tube outside the row of bags in the compartment through a specific pulse valve. I can. Airflow through the compartments is eliminated during the cleaning cycle when the isolation door closes. In the cleaning process, air is blown into the bag from the front of the impulse valve for about 0.2 seconds. The compartment remains offline during pulse processing. However, this period can be longer or shorter depending on your needs. The compartment returns to the stream when you intuitively reopen the isolation / poppet. Through a process called offline cleaning, the other compartments are cleaned one at a time until all the bags in the bag house have been cleaned. Bag filters achieve the lowest emission levels ever, but allow for very specialized bag cleaning, as is often the case with bag filters attached to low bulk products / dust.